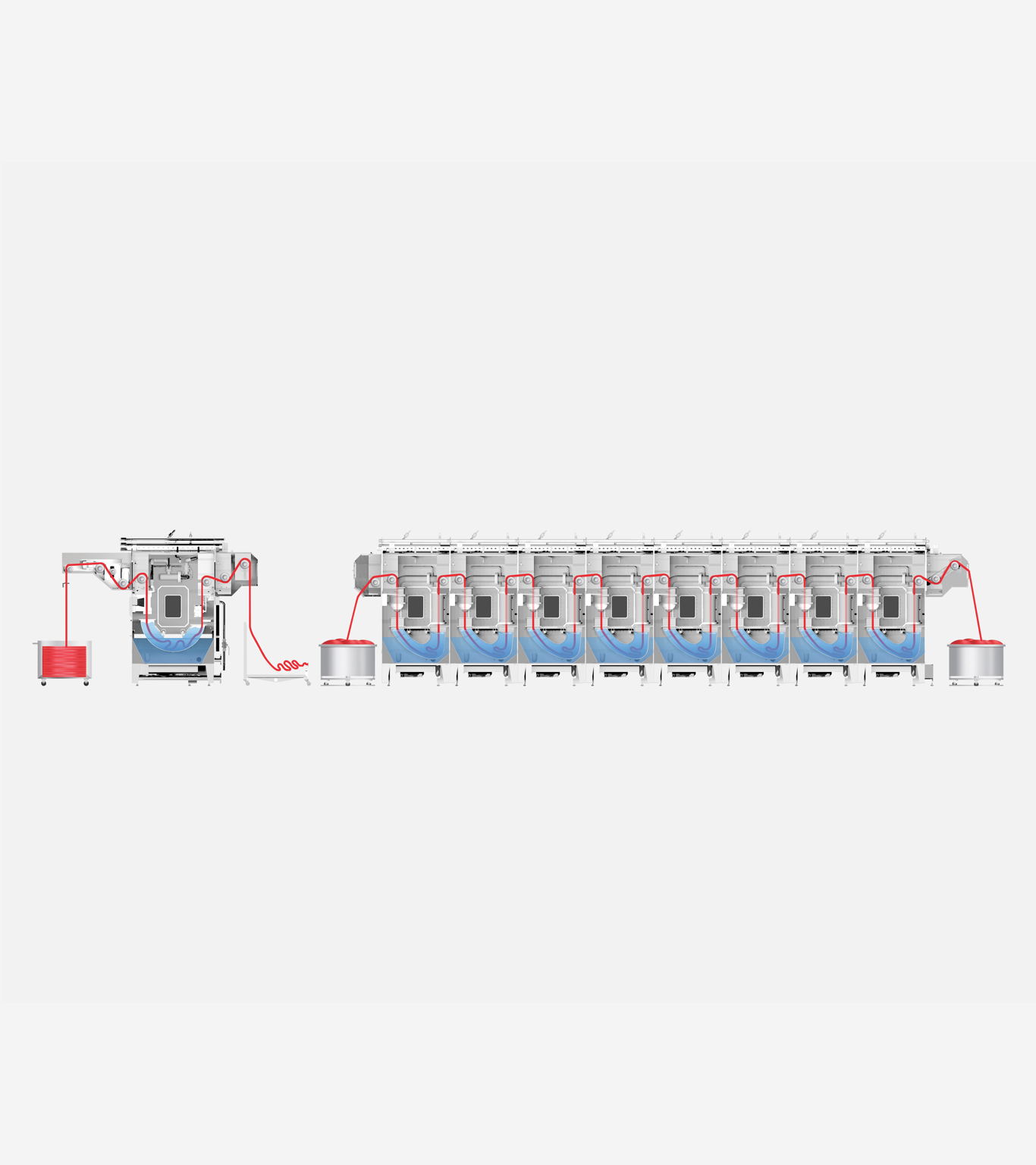

HIGH EFFICIENCY

HIGH EFFICIENCY

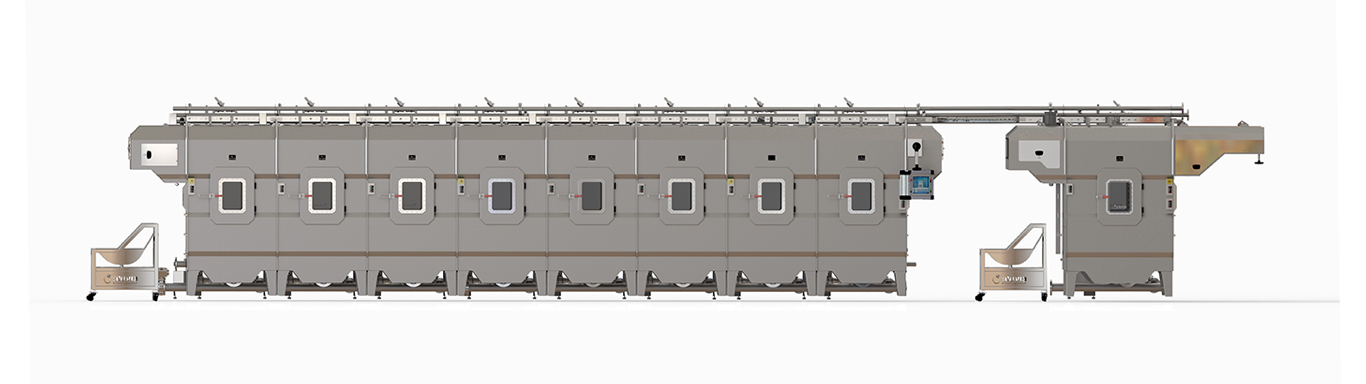

HIGH PRODUCTIVITY

HIGH PRODUCTIVITY

HIGH QUALITY

HIGH QUALITY

ALL TYPES OF FABRICS

KNITTED AND WOVEN

KNITTED AND WOVEN

ALL TYPES OF FIBRES

CELLULOSIC AND SYNHTHETIC

CELLULOSIC AND SYNHTHETIC

ALL TYPES OF DYES

REACTIVE AND DISPER

REACTIVE AND DISPER

ALL TYPES OF FABRICS WEIGHT

40 - 900 GR/SQM

40 - 900 GR/SQM

ALL TYPES OF PRINTINGS

ROTARY AND DIGITAL

ROTARY AND DIGITAL

ALL TYPES OF TEXTILE

APPAREL, HOME TEXTILE

APPAREL, HOME TEXTILE

LESS ENERGY

LESS ENERGY

HIGH productivity

HIGH productivity

HIGH Quality

HIGH Quality