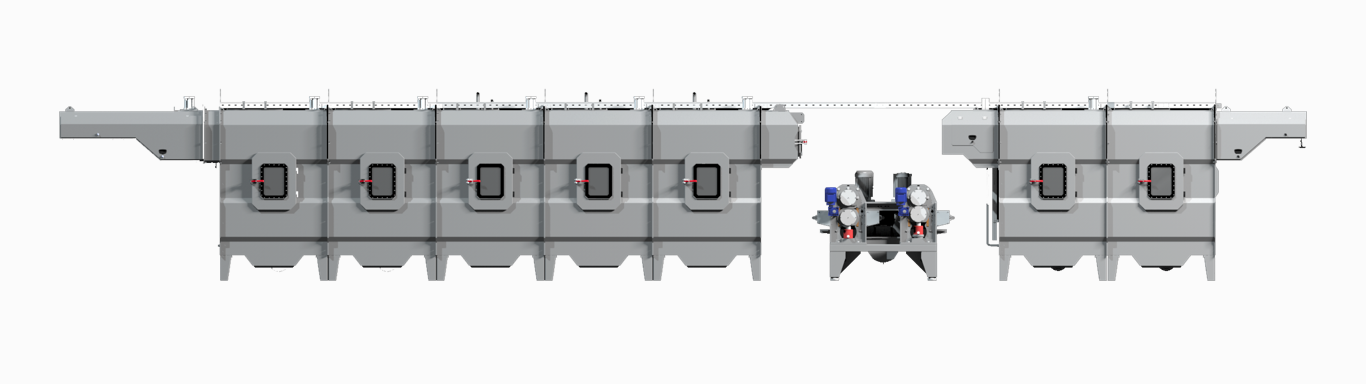

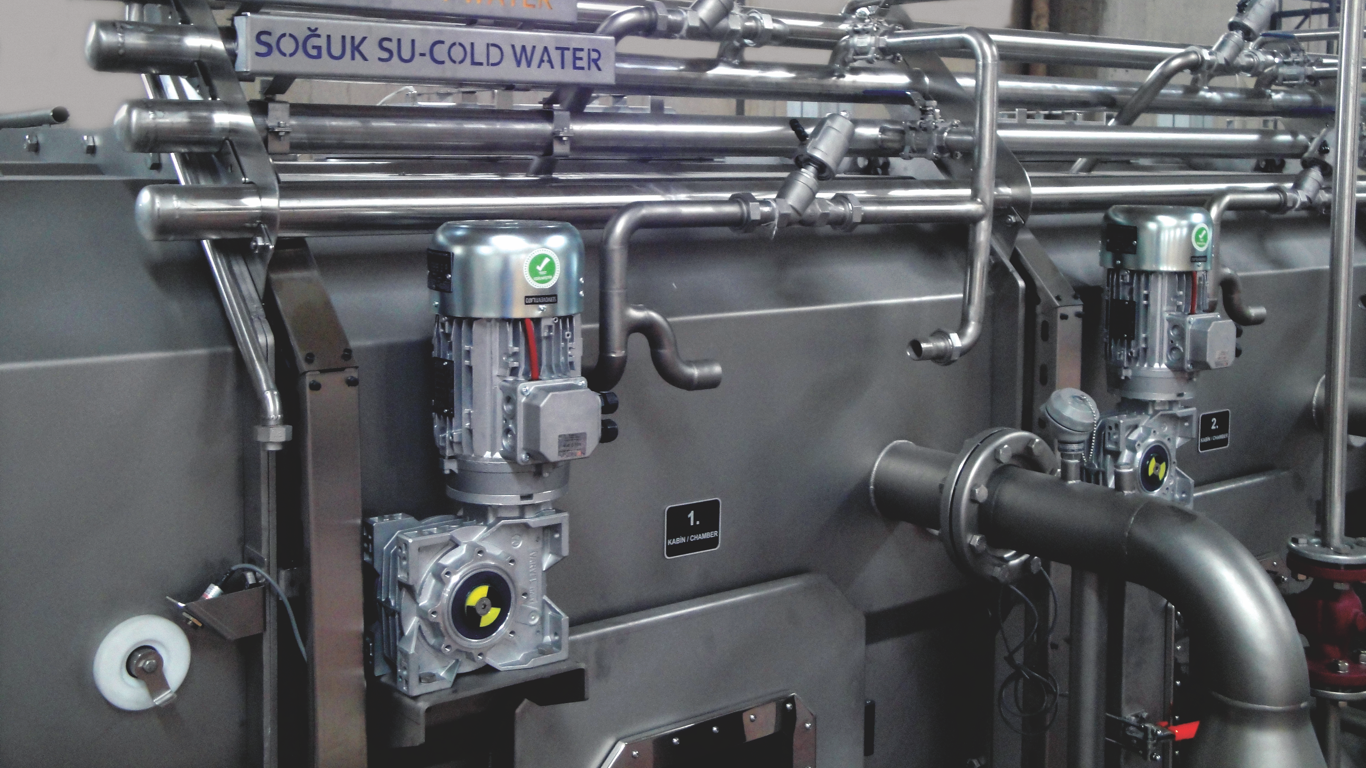

HIGH EFFICIENCY

HIGH EFFICIENCY

HIGH PRODUCTIVITY

HIGH PRODUCTIVITY

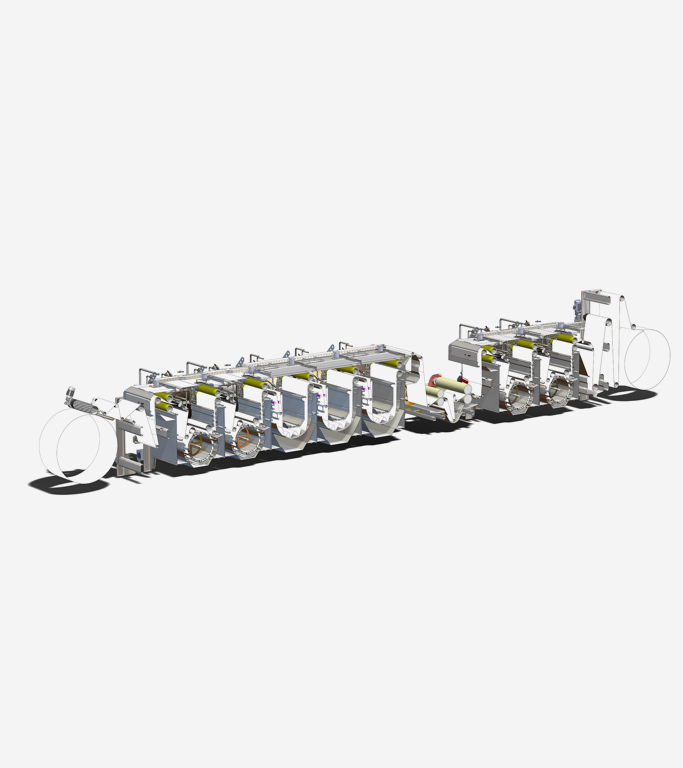

HIGH QUALITY

HIGH QUALITY

HIGHER WHITENESS

HIGHER HYDROFILITY

HIGHER CAPILARITY

NO CREASE MARKS NO DRYING SPOTS

NO HEAD AND TAIL, RIGHT LEFT DIFFERENCES

LESS ENERGY

LESS ENERGY

HIGH productivity

HIGH productivity

HIGH Quality

HIGH Quality